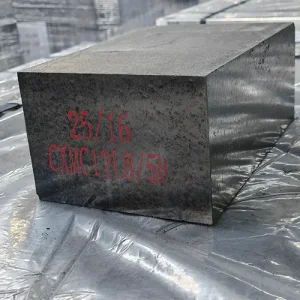

Types of Ramming Mix:

The refractory material to be rammed with the rammer is generally called a ramming material (meaning a material for the rammer construction), and there are roughly two types. First, a ramming material that contains a binding liquid such as coal tar pitch and exhibits a certain degree of strength at room temperature after construction is called a wet (wet) ramming material. A ramming material having a low strength is called a dry ramming material.

EAF Dry Ramming Mix Advantages:

The advantage of the dry ramming material is that the construction is very easy and a high packing density can be obtained as compared with the wet ramming material. That is, since it is a material composed of dried grains, it has good fluidity when struck or vibrated, and is easy to fill in the voids.

Reviews

There are no reviews yet.