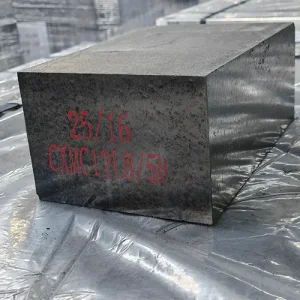

Magnesia Brick Introduction:

Magnesia bricks are alkaline refractory products with sintered magnesia (MgO ≥85%) as the main component. They are specially designed to withstand the erosion of high-temperature alkaline slag (such as CaO, FeO) and are widely used in high-temperature furnace linings in the steel, non-ferrous metallurgy and cement industries.

Our factory uses high-grade magnesia and strict process to produce magnesium oxide content of more than 90%, with periclase crystalline phase mainly basic refractories.

Magnesia Brick Advantages:

Magnesia brick has high refractoriness, good alkali resistance slag resistance, high load softening starting temperature, but poor thermal shock resistance. Sintered magnesia bricks to magnesia brick as raw material, crushing, ingredients, kneading, after molding at a high temperature 1550 ~ 1600 ℃ firing, high-purity products in firing temperature above 1750 ℃. Unfired magnesite bricks is added to the appropriate chemical binding agent in the magnesia by mixing, forming, drying made.

Mainly used for steelmaking basic open hearth furnace bottom and the furnace wall, the permanent lining oxygen furnace, non-ferrous metal smelting furnace, high-temperature tunnel kiln, calcined magnesia brick and cement rotary kiln lining, furnace and hearth furnace wall, glass furnace regenerator checker bricks and so on.

Reviews

There are no reviews yet.