Corundum brick introduction:

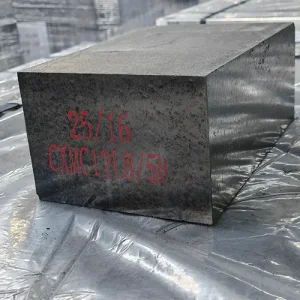

Corundum brick uses high-quality corundum as main raw materials. In the making process, firstly we should deploy a scientific formula and add excellent performance additives, then the bricks will be moulded under high presure and sintered under high temperature, finally made the corundum bricks.

Advantages of corundum brick:

Corundum brick can be divided into sintered corundum brick and fused corundum brick. Corundum brick has advantages of high strength, excellent wear resistance and strong anti-slag erosion, long service life and other characteristics. Corundum brick and chrome corundum brick, corundum mullite brick all can reduce the number of shutdown maintenance, thus saving maintenance costs, improve the furnace operating rate.

Corundum brick uses:

Corundum brick is a kind of high quality furnace lining materials and kiln materials for large blast furnace, rolling furnace and melting furnaces and kilns for refractory material, glass, chemical, ceramic, nonferrous metallurgical.

Corundum brick is a kind of high alumina refractory bricks, and mainly produced and applied as special refractory mateirals in extreme working conditions. Corundum brick is made of high purity fused alumina powder, white fused alumina oxide or tabular alumina, adding with other binders like refractory clays, reactive alumina powder, and high purity silica.

Corundum bricks are calcined at high temperatures to form a matrix with mullite, mullite-corundum or corundum, which making corundum brick with excellent volume stability structure and service temperature can be reach to 1900°C.

Reviews

There are no reviews yet.